Bend Park and Recreation District

- fitness & swim

-

-

Hiring Lifeguards

Hiring Lifeguards

-

- parks & trails

-

-

Work for BPRD

Work for BPRD

Work for BPRD

-

- activities

-

-

By Category (A-M)

-

- facilities

-

- about

-

-

- Contact Information

- How To Register

- Air Quality and Operations

- Delays and Cancellations Report

- Accessibility

- Advancing Diversity, Equity and Inclusion (DEI)

- Board of Directors & Meeting Info

- Lost and Found

- Recreation Scholarships

- Servicios en Español

- Planning and Development

- Employment

- Volunteer with BPRD

- Public Health Advisory: COVID-19

-

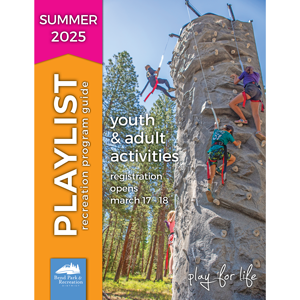

Playlist

Playlist Calendar

Calendar Board

Board News

News Jobs

Jobs Volunteer

Volunteer

- Register

- Overview

- Features

- Fees

- Rules

- Schedules & Events

- Swimming

- Fitness

- Parties & Rentals

- Childcare

- Pool Cover Update

- Contact Information

- How To Register

- Air Quality and Operations

- Delays and Cancellations Report

- Accessibility

- Advancing Diversity, Equity and Inclusion (DEI)

- Board of Directors & Meeting Info

- Lost and Found

- Recreation Scholarships

- Servicios en Español

- Planning and Development

- Employment

- Volunteer with BPRD

- Public Health Advisory: COVID-19

- home

- job descriptions

- Fleet Technician 2

Fleet Technician 2

Summer Playlist

Class Title: Fleet Technician 2

Class Code: FLEET TECH 2

Hourly: $27.33 - $36.16 | Monthly: $4736.59 - $6267.61 | Annually: $56839.07 - $75211.35Benefits: Full-time

OVERVIEW:

This classification is responsible for performing a full range of skilled mechanical repairs and preventive maintenance on a variety of vehicles and equipment including outdoor power equipment and performs welding and fabrication duties.

DISTINGUISHING CHARACTERISTICS:

The Fleet Technician performs skilled maintenance, major mechanical repairs while also performing welding and fabrication duties. Performs semi-skilled repairs and assist with major repairs while performing limited electric repairs.

SUPERVISION RECEIVED:

Works under the general supervision of a Manager. Carries out work independently, but work and decisions are typically reviewed prior to final execution.

SUPERVISION EXERCISED:

Supervision is not normally a responsibility of this position. However, may provide direction and training to Park Maintenance staff on equipment operation.

EXAMPLES OF DUTIES:

The information provided below encompasses the typical duties and capabilities linked with this classification. Duties may include, but are not limited to the following:

- Performs preventive and scheduled maintenance on foreign and domestic, light, heavy duty, gas and diesel vehicles and equipment including engine tune-ups, fluid and filter changes for engines, automatic and manual transmissions, front and rear differentials, transfer cases, hydraulic systems and other related systems; brake systems, steering and suspensions, exhaust systems, lubrication of steering, chassis, suspension and drive train components, maintains preventive maintenance schedules and logs.

- Performs major mechanical repair and overhaul on vehicles and equipment including engine, transmission, differential, final drive, front end, hydraulic, cooling, heating and related systems; emergency and roadside repairs.

- Diagnoses, troubleshoots, repairs and installs electrical systems and components including charging and starting systems, chassis wiring, engine performance, fuel delivery, mechanical and drivability problems.

- Installs, replaces, and repairs accessories and safety equipment on vehicles and equipment including ladder racks, beacon lights, backup alarms, trailer connectors, safety cone racks, tool boxes, and hitches.

- Services and repairs outdoor power equipment such as chain saws, weed trimmers, hedge trimmers, push mowers, backpack blowers, lawn edgers, and pressure washers.

- Performs safety inspections on vehicles and equipment; makes necessary repairs as needed; restocks vehicle safety supplies such as first aid kits, triangle flare kit, and fire extinguishers.

- Drives vehicles to sites.

- Assists with set up and breakdown of events.

- Performs welding and structural repairs on district vehicles and equipment; fabricates and installs ladder racks, outdoor power equipment and tool storage containers for vehicles and equipment; fabricates a wide variety of projects and tools to assist staff in their work area improving production and safety; other welding and fabrication projects may be performed throughout the district fabricating gates, handrails, kiosks, fencing, and bollards.

- Maintains a clean and organized garage, workspace, shop tools and repair equipment.

- Practices safe work habits; operates equipment and tools safely and with care; evaluates and determines when vehicles and equipment must be “red-tagged” for safety reasons.

- Provides training and guidance to other employees regarding operational and mechanical safety.

- Reduce or eliminate the quantity of hazardous chemicals and materials acquired, generated, and/or used in the scope of work. Safely handle and properly dispose of hazardous waste materials.

- Acts as a Mandatory Reporter; reports incidents of child abuse/neglect.

- Performs other job related duties as assigned.

KNOWLEDGE, SKILL, AND ABILITY REQUIREMENTS:

The individual in this classification is expected to possess and exhibit the following knowledge, skills and abilities.

Strong Knowledge of:

- Methods and techniques of mechanical parts, supplies and related tools;

- Lubrication systems including oils and gases used in the overhaul, repair, service and maintenance of gasoline and diesel-powered vehicles and equipment techniques;

- Operations and maintenance of a wide variety of hand tools, power and shop tools and equipment;

- Methods and techniques of materials, tools and equipment used in metal fabrication and welding, maintenance and repair;

- Effective safety practices and procedures;

- Pertinent Federal, State, and local laws, codes and safety regulations.

Skill and Ability to:

- Effectively diagnose, repair, maintain and operate a variety of diesel and gasoline powered vehicles and equipment;

- Effectively operate a wide variety of hand, power and shop tools and equipment in a safe and effective manner;

- Effectively perform technical diagnostic and repairs in a timely manner;

- Effectively fabricate, weld and modify equipment including specialty items;

- Demonstrate use of computers and software programs including those specifically designed for fleet diagnostics and operations;

- Read, analyze, interpret and understand data from various manuals, blueprints and schematics to solve basic problems;

- Use simple math and mathematical reasoning;

- Learn and apply new information or new skills to relevant situations;

- Maintain accurate records;

- Work independently while also able to work cooperatively with others;

- Effectively communicate both orally and in written form by phone, e-mail or in person;

- Exercise initiative and judgment in completing tasks and responsibilities; and

- Establish and maintain effective, cooperative and respectful working relationships with all contacts.

QUALIFICATIONS:

The following are minimum qualifications for this classification.

Education, Experience, and Training:

- High school diploma or equivalent; two years of specialized training in an accredited automotive and/or heavy equipment systems repair program preferred; AND

- Three (3) years as an automotive/heavy equipment mechanic with welding and metal fabrication and electronic diagnosis experience; OR

- Any satisfactory combination of education, experience and training.

Licenses and Certifications:

- Possession of or ability to obtain within 30 days of hire a valid Oregon Driver’s license

- Possession of or ability to obtain within 30 days of hire a valid Forklift Operation certification

- Possession of a valid AWS Welders Certification, preferred

- Possession of a valid ASE Certification, preferred

WORKING CONDITIONS:

The following are working conditions, including environmental and physical demands, required for this classification.

- Work is performed primarily in a shop environment, occasionally outside; regular exposure to various weather conditions.

- Physical demands include crouching, crawling, kneeling, climbing, balancing, bending, twisting, pushing, pulling, standing, walking, grasping, and occasional lifting, moving and carrying objects up to 50 pounds unassisted.

- Seeing/observing includes close, distance, peripheral and depth perception and the ability to adjust focus.

- Repetitive hand and arm motions and significant finger dexterity.

- Work under deadlines with interruptions.

- Exposure to equipment with crushing potential, moving mechanical parts, hazardous chemicals, vibration, dust, fumes, toxic odors, electrical energy, high noise levels, and slippery surfaces.

- Work requires operation of a vehicle or equipment on public roadways.

STATUS:

Non-Exempt

Full-Time

Benefits: Full-time

Current Job Opportunities